Why Are Portable Laser Cleaners Becoming More Popular?

Laser cleaning machines are gradually replacing traditional methods like chemical cleaning, sandblasting, or manual grinding due to their efficiency, eco-friendliness, and zero consumables. Laser cleaning machine can quickly remove rust, paint, grease, and oxides while minimizing damage to the base material and reducing maintenance costs.

Currently, laser cleaning machines are mainly divided into two types: CW laser cleaning machine and pulse laser cleaning machine, each designed for different cleaning needs.

Continuous Wave VS Pulsed Laser Cleaning

CW laser cleaning machine deliver high power (typically above 1000W) and are ideal for large-area rust removal or heavy steel structures. They work quickly but generate continuous heat, which can damage thin-walled or delicate parts.

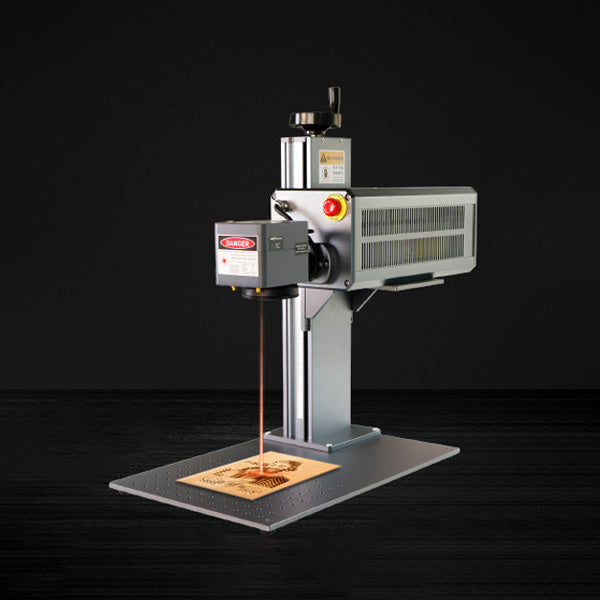

Pulse laser cleaning machine use short, high-energy pulses in intervals(power typically 100W-300W), significantly reducing heat impact. This makes them better suited for applications where surface quality is critical or where heat-sensitive or precision components need cleaning, such as electronic parts, molds, or artifact restoration. To adapt to various working environments and complex shapes, more people are choosing portable pulse laser cleaning machine for easy multi-scene use.

Advantages of Portable Pulsed Laser Cleaners

Compared to stationary systems, portable pulse laser cleaning machine are compact and flexible, making them ideal for on-site jobs or spot cleaning on large, irregular objects. Handheld laser cleaning machine combine low heat impact with easy mobility, handle a wide range of materials (metals, plastics, stone, etc.), and offer versatile cleaning for tasks that demand both precision and flexibility.