What Are the Benefits of Laser Welding Machines?

Laser welding technology is transforming industries with its precision, efficiency, and versatility. Compared to traditional welding methods, laser welding machines provide significant benefits that enhance productivity and quality. Here’s why businesses are turning to laser welders for advanced manufacturing solutions.

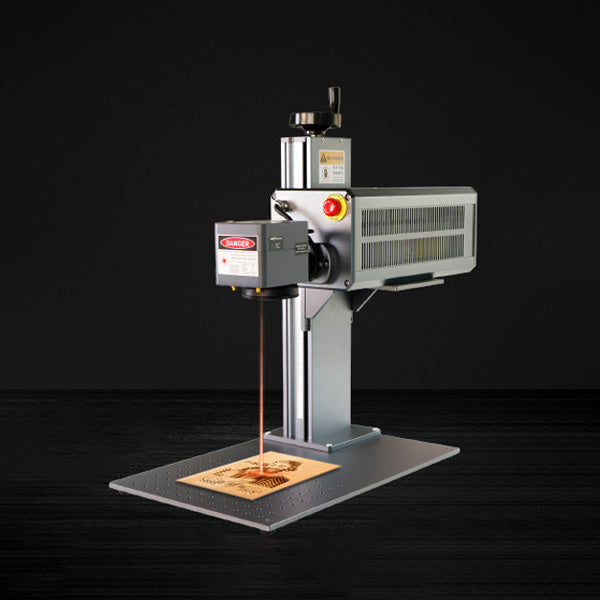

1. Exceptional Precision & Strong Welds

A laser welding machine generates a concentrated beam of high-energy light, allowing for fine, deep welds with minimal heat impact. This ensures excellent structural integrity while reducing warping or distortion. The ability to create seamless and aesthetically pleasing welds makes laser welders ideal for precision applications.

2. Contact-Free Welding for Delicate Materials

Unlike conventional welding, laser welder machines use a non-contact process, minimizing physical stress on the material. With fiber optic transmission, the laser can reach tight spaces and intricate parts, making it perfect for industries requiring micro-welding, such as electronics and medical device manufacturing.

3. High-Speed Processing & Energy Efficiency

With faster welding speeds and optimized energy usage, laser welding machines for sale help businesses enhance production rates while cutting operational costs. The precise heat control of laser welders also reduces energy waste, making them a cost-effective alternative to traditional welding methods.

4. Versatility for Various Materials & Applications

A laser welding machine can handle diverse materials, including stainless steel, aluminum, copper, titanium, and even ceramics. It excels in welding different material types and thicknesses, ensuring high-quality bonds for aerospace, automotive, and custom fabrication industries.

5. Eco-Friendly & Safer Operation

Traditional welding methods produce excessive smoke, fumes, and harmful gases. In contrast, laser welder machines generate minimal emissions, providing a cleaner and safer work environment. The absence of open flames or arcs also reduces workplace hazards.

6. Automation & Smart Integration

Modern laser welding machines seamlessly integrate with robotic arms, CNC systems, and AI-powered vision technology. This automation enhances precision, reduces labor costs, and improves repeatability in industrial production.

7. Minimal Post-Weld Processing & Lower Costs

Since laser welders create smooth and refined welds, they often eliminate the need for extensive post-processing like grinding or polishing. This lowers production costs and shortens turnaround times, making laser welding an efficient and cost-effective choice.

Find the Best Laser Welder for Your Business

At Fonland, we provide premium laser welders for sale, offering industry-leading solutions for manufacturing, automotive, electronics, and more. If you're looking for a laser weld machine price that delivers precision and performance, contact us today to explore our cutting-edge laser welding systems.