How to Choose a Right Laser Welding Machine?

With the wide variety of laser welder models available on the market, selecting the right one can be confusing. Each type has its own advantages, and the best choice depends on the materials you weld, your preferred machine type, and the desired welding results.

What Is Your Welding Purpose?

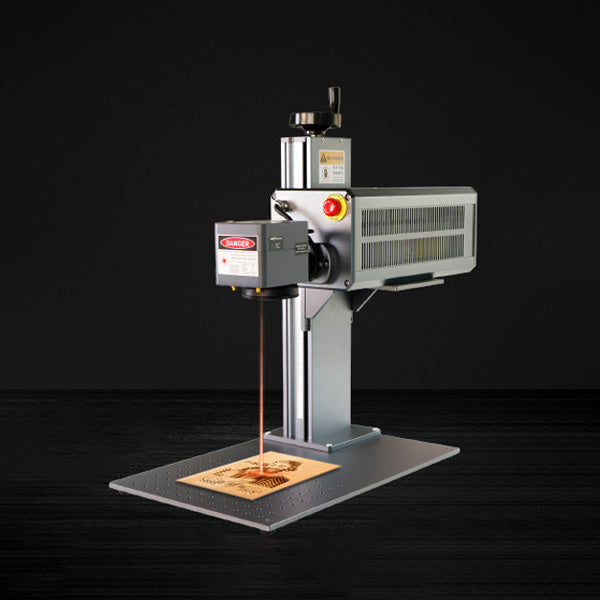

The first step in choosing a suitable welder is understanding your welding purpose. For fixed workshop operations or continuous production, laser cabinet-style welders provide higher stability and better thermal management. On the other hand, handheld laser welders are more flexible, portable, and efficient, making them ideal for light manufacturing, repair work, or small-batch production.

What Materials Do You Need to Weld?

Different materials require different types of lasers. For common metals such as stainless steel, aluminum, and carbon steel, fiber laser welding machines are the most practical choice, delivering clean seams and strong joints. For highly reflective materials like copper, gold, or silver, green or blue laser welding equipment offer better absorption and smoother welds.

Laser Output Modes

Laser welders come with two output modes. Continuous wave (CW) lasers are designed for deep and fast welding, making them ideal for thicker materials or structural joints. In contrast, pulsed lasers are better suited for precision or heat-sensitive components, such as thin sheets, electronic parts, or decorative pieces. Choosing the correct output mode ensures stable weld quality and prevents overheating or deformation.

Other Factors to Consider

Several technical factors should be considered before purchasing welder. The power output should match your material thickness, 1500W–2000W handheld laser welder can handle most thin metal applications. The cooling system affects durability, air-cooled machines are lighter and easier to move, while water-cooled machines are better for continuous or long-duration operation. User interface, ease of operation, and safety features also impact productivity and operator safety.

Conclusion

The best laser welding machine is not necessarily the most expensive one but the machine that fits your production needs. The key is to match your intended use with the desired welding results. Whether for industrial applications or small-scale production, making the right choice will help you achieve better outcomes and long-term reliability.